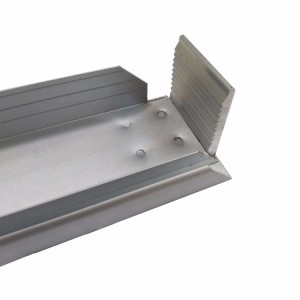

Mohala oa sehokedi sa sehokedi sa sehokedi sa lente ya letsatsi

Tlhaloso

Thepa ea Mechanical terata ea Solar Tabbing:

1. Elongation: E-Soft>=20% U-Soft>=15%

2. Matla a ho tsitsa:>=170MPa

3. Side camber: L<=7mm/1000mm

4. Sebaka se qhibilihang sa thini: 180 ~ 230°C

Motlakase Resistivity ea Koporo:

TU1<=0.0618 Ω·mm2/m; T2<=0.01724 Ω·mm2/m

Core Copper ea TU1 Off-Cu kapa ETP1:

1. Bohloeki ba Koporo > = 99.97%, Oksijene<=10ppm

2. Ho hanyetsa: ρ20<=0.017241 Ω·mm2/m

Ho hanyetsa Motlakase ha Ribone:

(2.1~2.5)X10-2 Ω·mm2/m

Botenya bo Platiloeng:

1) Hand-Soldering: 0.02-0.03mm ka lehlakoreng le leng

2) Machine-Soldering: 0.01-0.02mm ka lehlakoreng le leng

Sebopeho sa Lintho tse entsoeng ka Plated:

1) Lihlahisoa tse etellang pele:

A.Sn 60%, Pb 40%

B.Sn 63%, Pb 37%

C.Sn 62%, Pb 36%, Ag 2%

D. Sn 60%, Pb 39.5%, Ag 0.5%

2) Lihlahisoa tse se nang lead:

A. Sn 96.5%, Ag 3.5%(Bi)

B. Sn 97%, Ag 3% joalo-joalo

Mabapi le Ribone ea ho Tabbing & Bus Bar Ribone

Ribone ea PV e entsoe ka Copper le alloys e koahelang, 'me e arotsoe ka Ribone ea Tabbing le Bus bar ribone.

1. Ribone ea ho thaepa

Tabbing Ribone hangata e hokahanya mahlakore a matle le a mabe a lisele ka tatellano.

2. Ribone ea libese

Sebaka sa libese Ribone se tsepamisa mohala oa sele ka har'a lebokose la mateano le likanale tsa motlakase.

Mabapi le Coating Alloy:

Mofuta oa ho roala o khethoa ke moralo le tlhoko ea moreki. E arotsoe ka lesela le nang le loto le le sa shoeng. Hajoale mofuta oa ho roala o nang le lead o sebelisoa haholo, empa nakong e tlang o tla ntlafatsoa hore e be mofuta oa ho roala o se nang lead.

litlhaloso

| SIZE(mm) | BOTETE(mm) | SEBELISA KOPO | MAMELLO | ||

| WXT | Base Copper | Apara ka lehlakore | Bophara | Botenya | |

| 0.6x0.12 | 0.0500 | 0.0150 | TU1 | +/-0.05 | +/-0.015 |

| 0.8x0.08 | 0.0500 | 0.0150 | TU1 | ||

| 0.8x0.10 | 0.0500 | 0.0250 | TU1 | ||

| 1.0x0.08 | 0.0500 | 0.0150 | TU1 | +/-0.05 | +/-0.015 |

| 1.0x0.10 | 0.0500 | 0.0250 | TU1 | ||

| 1.5x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.5x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 1.6x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.6x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 1.6x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 1.8x0.15 | 0.1000 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 1.8x0.16 | 0.1100 | 0.0250 | TU1 | ||

| 1.8x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 1.8x0.20 | 0.1500 | 0.0250 | TU1 | ||

| 2.0x0.13 | 0.0800 | 0.0250 | TU1 | +/-0.05 | +/-0.015 |

| 2.0x0.15 | 0.1000 | 0.0250 | TU1 | ||

| 2.0x0.16 | 0.1100 | 0.0250 | TU1 | ||

| 2.0x0.18 | 0.1250 | 0.0275 | TU1 | ||

| 2.0x0.20 | 0.1500 | 0.0250 | TU1 | ||

Mokhoa oa Theknoloji

1, Ho etsa lithapo tse chitja ho isa lithapong tse bataletseng ka ho taka le ho bilika

2, Phekolo ea mocheso

3, Hot-dip tinning

4, spooling e nepahetseng

Copper base ke likhoele tsa koporo tse se nang oksijene tse hlohlelletsoang ke lisebelisoa tsa ho roala ka nepo tse tsoang kantle ho naha ho tsoa Jeremane.

E boreleli ebile ha e na moeli, boima bo bonolo bo ka fetoloa ho latela tlhoko ea bareki.

Ka theknoloji e khethehileng ea foromo, jase ea alloy ea tin e hlahisoa ke lisebelisoa tsa profeshenale tsa ho qoelisa tse chesang tse tsoang Japane. Coat suface e khanya ebile e lekana, e na le ts'ebetso e ka khonehang le antioxidant e matla e thusang ho fokotsa chai ea welding. Botenya ba eona bo ka fetoloa ho latela tlhoko ea bareki.

Ribone e ka etsoa ho odara ho latela mojule oa letsatsi le boholo ba eona

Pontšo ea Sehlahisoa